Short Lead Time for Best Marine Water Hose - Mainline Submarine Hose – Zebung

Short Lead Time for Best Marine Water Hose - Mainline Submarine Hose – Zebung Detail:

Construction & Material

Construction & Material

Main Carcass

Main Lining / Inner Tube: Smooth, oil and fuel resistant Pure Seamless and Extruded Acrylontrile Butadiene Rubber (NBR);

Safety Lining: special construction to prevent defects or damage cause by incidental tearing or superficial damages of the main lining;

Reinforcements: Multiple Plies of High Tensile Textile cord. One embedded helical Body Steel wire.

Single Carcass And Double Carcass

Outer Cover:Smooth black, Synthetic Rubber Resistant to Abrasion, Oil, Sea Water and Sunlight.

Fittings:End connections built in during manufacture. ASME B 16.5 Class 150lb or 300lb Weld Neck Flat Face or Raised Face on request.

Hose Tests:All tests according to GEPHOM 2009 and Customer detail.

Standards and Specifications

Zebung single carcass hoses are designed and produced in full accordance to OCIMF standards. These products are also subjected to manufacturing and testing requirements dictated by ISO 9000:2001 quality standards.

Rated working pressure

The oil hoses have a RWP of at least 15 bar. 19 bar and 21 bar hoses are also available if specified by the customer. They are suitable for operation at an internal pressure from minus 0.85 bar to the RWP.

Flow Velocity

The linings of Zebung submarine hoses are constructed from elastomers and fabrics suitable for continuous operation at a flow velocity of 21m/s.

Application

The submarine hoses are suitable for use with crude oil and liquid petroleum products from -20℃ to 82℃, and an aromatic hydrocarbon content no greater than 50% by volume.

Electrical Continuity

A low resistance connection will be provide with a copper wire and helix steel wire.

Characteristic

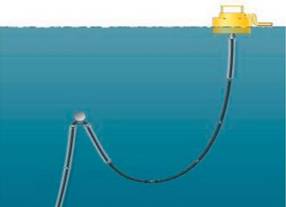

1. connecting tanker and discharge facilities

2. rated working pressure: 21 bar

3. electrical continuity: electrical continuous or discontinuous

4. leak detection system: after the failure of the primary carcass, the detector will react to the leakage to remind the operator to remove the damaged hose to avoid economic loss and environmental pollution.

Specifications can be designed by customer requirements.

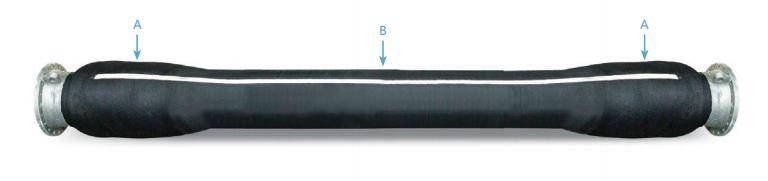

| I.D. / mm | Weight in air / KG | O.D. / mm | M.B.R. / m | |||

| 9.1m | 10.7m | 12.2m | A | B | ||

| 150(6”) | 342/137 | 380/152 | 418/167 | 305 | 210 | 0.6(2.0’) |

| 250(10”) | 639/272 | 712/299 | 785/326 | 415 | 320 | 1.0(3.3’) |

| 300(12”) | 810/305 | 902/334 | 994/363 | 485 | 375 | 1.2(4.0’) |

| 400(16”) | 1216/560 | 1359/619 | 1502/678 | 575 | 475 | 1.6(5.3’) |

| 500(20”) | 1600/778 | 1792/858 | 1984/938 | 695 | 580 | 2.0(6.6’) |

| 600(24”) | 2404/1180 | 2680/1309 | 2956/1438 | 810 | 700 | 2.4(8.0’) |

12 Inch underwater tubing certificate

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Short Lead Time for Best Marine Water Hose - Mainline Submarine Hose – Zebung , The product will supply to all over the world, such as: Mauritius, Florence, UK, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

Leave your details and we'll contact you at the first time.