Fep Hose

Applications: Widely used in petroleum industry,food and beverage,the chemical industry,cosmetics,API and biopharmaceuticals industries.Suitable for all kinds of corrosive chemicals, except chlorine trifluoride, chlorine and fluorine gas(dry),oxygen difluoride,phosgene and molten alkali metals (such as sodium). For road and rail tankers,unloading bays as well as mobile and fixed installations in chemical,pharmaceutical and allied industries.

Advantages:

Smooth inner tube for maximum flow and easier washing out (with steam up to +150°C).

Excellent chemical and mechanical properties.

Inner tube in accordance with FDA 21.CFR.177.1550

Technical Description:

Inner tube: Chemical resistant FEP (Fluorinated Ethylene Propylene), white, smooth.

Reinforcement: Synthetic textile cord with spiral steel helix.

Cover: Chemical and weather resistant EPDM, black or green.

Temperature range: -40°C to +150°C(intermittent to +180℃)

Standard:

EN12115/FDA 21.CFR.177.1550

Own film production base

The quality of film directly determines the quality of hose. Therefore, zebung has invested a lot of money to build a film production base. All hose products of zebung adopt self-produced film.

Multiple production lines to ensure production progress

Our factory has many modern production lines and a large number of experienced technical engineers. It not only has high quality production quality, but also can ensure the customer's requirements for the supply time of products.

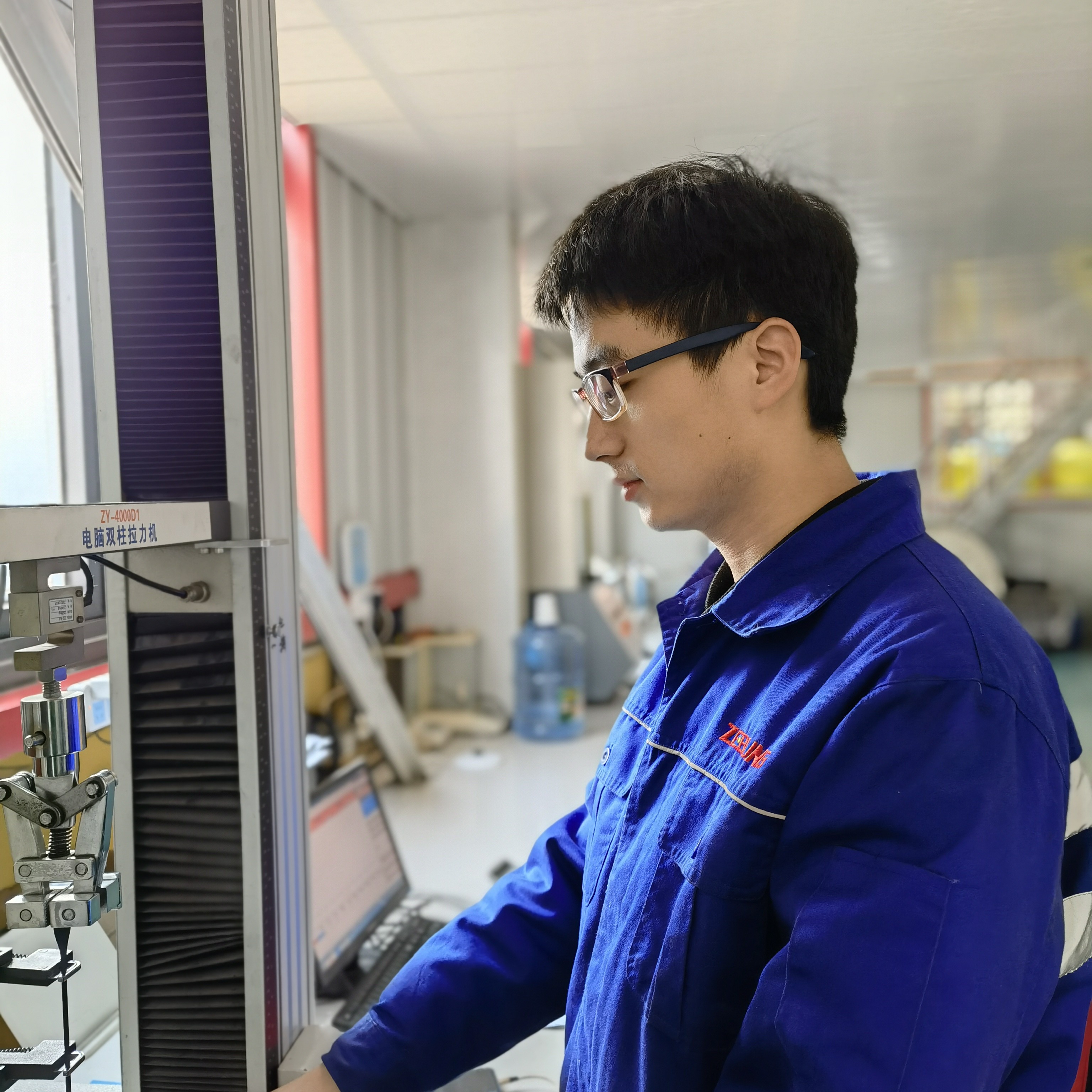

Each pipeline product is subject to strict inspection before leaving the factory

We have established a high-tech product and raw material testing laboratory. We have been committed to the digitization of product quality. Each product needs to go through a strict inspection process before it can leave the factory after all product data meet the requirements.

Covering the global logistics network and strict finished product packaging and delivery process

Relying on the distance advantages of Tianjin port and Qingdao port, Beijing Capital International Airport and Daxing International Airport, we have established a fast logistics network covering the world, basically covering 98% of countries and regions around the world. After the products are qualified in the off-line inspection, they will be delivered at the first time. At the same time, when our products are delivered, we have a strict packing process to ensure that the products will not cause losses due to logistics during transportation.

ANY QUESTIONS?

方1.jpg)

方1.jpg)

方1.jpg)

方1.jpg)

方1.jpg)

方1.jpg)