1. What are the factors that affect the aging of rubber hoses?

1). Environmental factors

● Oxygen and ozone: Oxygen and ozone are one of the main culprits of rubber aging. They can react with rubber molecules in a free radical chain reaction, causing molecular chain breakage or excessive cross-linking, thereby changing the properties of the rubber. Although Zebung Technology’s products have been specially treated to improve aging resistance, they will still be affected by long-term exposure to high-concentration ozone environments.

● Heat: Increasing the temperature will accelerate the thermal cracking or thermal cross-linking of rubber, promote oxidation reactions, and lead to thermal oxidation aging. Rubber hoses working in high-temperature environments, such as steam pipes and radiator pipes, are more susceptible to such effects.

● Light: Ultraviolet rays are the main culprit of photoaging, which directly causes the breakage and cross-linking of rubber molecular chains. At the same time, the free radicals generated by absorbing light energy will accelerate the oxidation chain reaction.

● Moisture: When rubber is immersed in a humid environment or in water, water-soluble substances and clear water groups are easily extracted and dissolved by water, causing hydrolysis or absorption, and accelerating aging.

2). Medium factors

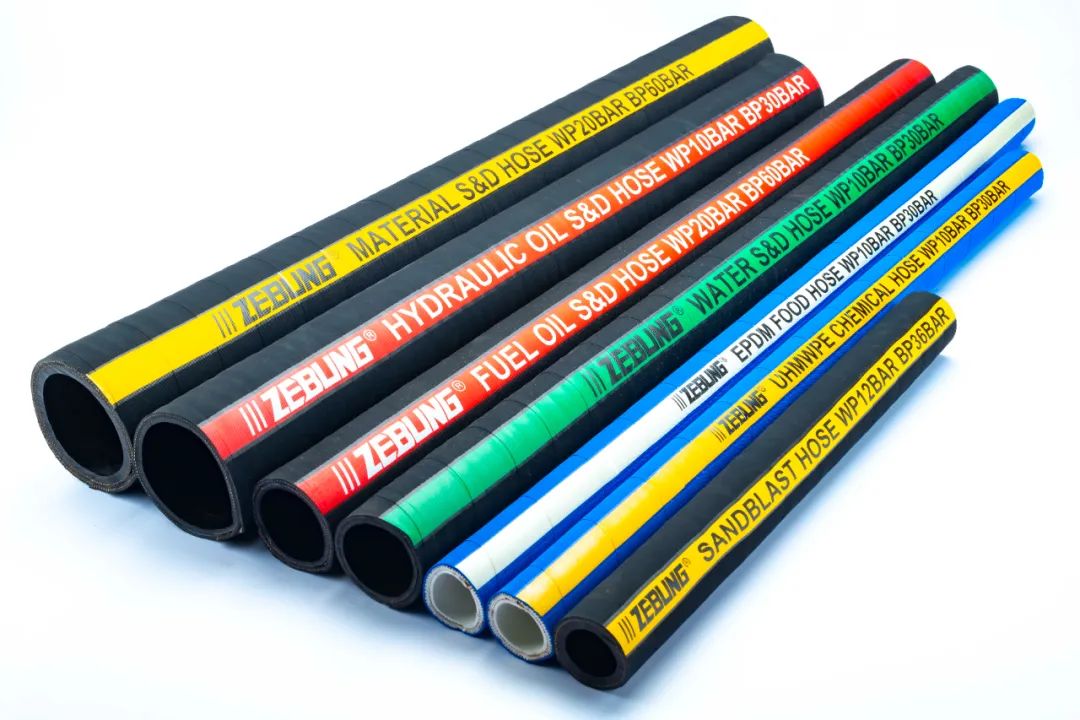

The medium transported by the rubber hose also has a significant impact on its aging rate. For example, corrosive media such as oils and chemicals will accelerate the aging process of rubber. Although Zebung Technology’s chemical hoses and food hoses have excellent corrosion resistance, they still need to be careful when in contact with specific media for a long time.

3). Mechanical stress

Repeated mechanical stress will break the rubber molecular chain, generate free radicals, and then trigger an oxidation chain reaction. During the installation and use of the hose, if it is excessively bent, stretched or squeezed, it will accelerate aging.

2. What are the effective measures to prevent the aging of rubber hoses?

1). Reasonable selection and use

● Choose the appropriate type of rubber hose according to the specific use environment and medium characteristics. For example, when transporting oil substances, a nitrile hose with good oil resistance should be used.

● During use, avoid dragging the hose, excessive bending, or long-term mechanical stress beyond the design range.

2). Optimize storage conditions

● Before storage, ensure that there is no corrosive medium residue inside the hose and avoid excessive bending.

● The storage environment should be kept dry and ventilated, and stored in a cool place to reduce the impact of temperature, humidity and light on the hose.

3). Regular maintenance inspection

● Regularly inspect the appearance and performance of rubber hoses to promptly detect and deal with aging, cracks, deformation and other problems.

● For hoses that have been used for a long time, they should be replaced according to actual conditions to avoid safety hazards caused by aging.

4). Enhanced protective measures

● In places that are susceptible to ultraviolet radiation, sunshades can be installed or other sun protection measures can be taken.

● For hoses working in extreme environments, protective measures such as protective sleeves or coatings can be considered to improve their aging resistance.

With rich R&D experience and advanced technical means, Zebung Plastic Technology Co., Ltd. continues to launch high-performance, aging-resistant rubber hose products. However, to ensure that the hose maintains a good performance during use, it is also necessary to take scientific and effective protective measures in combination with the specific use environment and conditions. Only in this way can the service life of the rubber hose be maximized and the smooth progress of production be guaranteed.

Post time: Aug-06-2024