In the vast blue territory, the ocean is not only the cradle of life, but also an important channel for global economic and energy transportation. With the continuous growth of global energy demand, especially the irreplaceable status of oil as the blood of industry, the development of marine oil hoses, as key equipment connecting offshore oil extraction, transportation and land processing, has not only witnessed the leap of human technology, but also profoundly affected the changes in the world’s energy pattern. This article aims to explore the development trajectory, technological innovation, challenges and future trends of marine oil hoses in the world.

1. The historical evolution of marine oil hoses

The history of marine oil hoses can be traced back to the mid-20th century. At that time, with the breakthrough of deep-sea oil exploration technology, traditional rigid hose could no longer meet the needs of complex and changeable marine environments. As a result, a soft, corrosion-resistant, easy-to-lay and maintain hose came into being and quickly became an indispensable part of deep-sea oil and gas field development. At first, these hoses were mainly used in shallow waters, but with the advancement of materials science and the improvement of manufacturing processes, they gradually penetrated into the seabed thousands of meters deep and became the “lifeline” connecting submarine oil wells with floating production storage and offloading units (FPSO) or land terminals.

2. Technological innovation and material innovation

The core competitiveness of marine oil hoses lies in their material selection and technological innovation. Early hoses mostly used rubber or synthetic rubber as the inner lining to resist the corrosion and wear of oil products. However, with the increasingly harsh use environment, especially the extreme conditions such as deep sea high pressure, low temperature, and high salinity, traditional materials can no longer meet the needs. Therefore, a series of new polymer materials such as polyurethane, fluororubber, thermoplastic elastomers, etc. have been introduced. These materials not only have excellent corrosion resistance, wear resistance and anti-aging properties, but also can maintain stable physical properties under extreme temperatures.

At the same time, in order to enhance the pressure bearing capacity and fatigue resistance of the hose, multi-layer composite structure design has become the mainstream. This design arranges materials with different properties in a specific order to form a multi-layer structure. Each layer has a specific function, such as the inner lining is responsible for isolating oil products, the reinforcement layer provides strength support, and the outer sheath protects the hose from erosion by the marine environment. In addition, advanced connection technology and sealing design have greatly improved the overall performance and reliability of the hose.

3. Challenges and solutions

Although marine oil hose technology has made significant progress, it still faces many challenges in practical applications. First of all, the complexity and changeability of the deep-sea environment places extremely high demands on the design, manufacture and installation of hoses. How to ensure the long-term and stable operation of hoses under extreme conditions is a major problem that researchers need to overcome. Secondly, with the increase in environmental awareness, higher requirements are placed on the environmental friendliness, recyclability and biodegradability of hose materials. Therefore, the development of more environmentally friendly hose materials has become the future development direction.

In response to these challenges, the industry has taken a series of measures. On the one hand, it strengthens international cooperation and exchanges, shares technological achievements and lessons learned, and promotes the formulation and improvement of industry standards; on the other hand, it increases R&D investment, continuously explores the application of new materials, new processes and new technologies, and improves the overall performance and competitiveness of hoses. At the same time, it focuses on the integration of environmental protection concepts and promotes the green transformation of hose products.

IV. Future Development Trends and Prospects

Looking ahead, the development of marine oil hoses will show the following trends: First, it will advance into deeper and farther waters. With the continuous deepening of deep-sea oil and gas resource exploration and development, hose technology will continue to upgrade to meet more demanding conditions of use; second, the level of intelligence and digitalization will be improved, and through the integration of sensors, the Internet of Things and other technologies, the real-time monitoring and intelligent early warning of the hose operation status will be realized; third, the widespread application of environmentally friendly materials will promote the development of hose products in a greener and more sustainable direction; fourth, standardized and modular production will improve the design, manufacturing and installation efficiency of hoses and reduce costs.

As one of the important equipment for the development of marine oil and gas resources, the development history of marine oil hoses has not only witnessed the continuous progress of human science and technology and the infinite possibilities of innovative spirit, but also heralded a new chapter in the future use of marine energy. With the accelerated advancement of global energy transformation and the vigorous development of the marine economy, marine oil hoses will surely usher in a broader development space and unlimited opportunities.

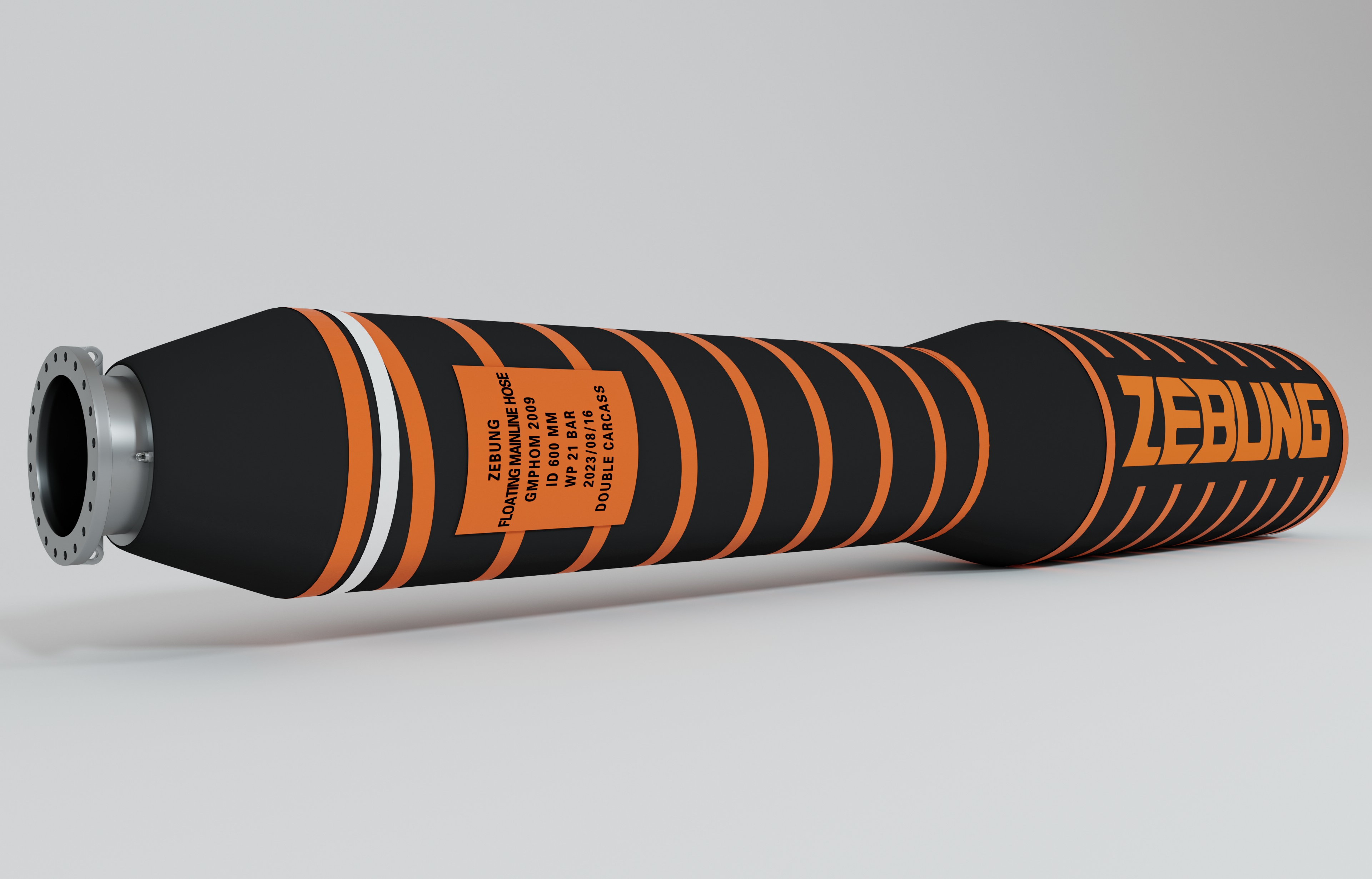

As one of the core manufacturers of global marine oil hose, Zebung will continue to work hard to produce better products and provide better user experience for global customers.

Post time: Sep-06-2024