The catenary anchor leg single point mooring system (CALM) usually consists of a buoy that can float on the sea surface and a pipeline laid on the seabed and connected to the land storage system. The buoy floats on the sea surface. After the crude oil on the tanker enters the buoy through the floating hose, it enters the submarine pipeline from the underwater hose through the pipeline terminal manifold (PLEM) and is transported to the crude oil storage tank on the shore.

In order to prevent the buoy from drifting long distances with the waves, it is connected to the seabed with several huge anchor chains. In this way, the buoy can float and move with the wind and waves within a certain range, increase the buffer effect, reduce the risk of collision with the tanker, and will not drift away due to the waves.

1、Floating hose system

The floating hose system can be composed of a single pipeline, or it can be composed of two or more pipelines. The more pipeline groups, the greater the oil unloading capacity. Each pipeline is composed of a tanker rail hose, a tail hose, a reducer hose, a mainline hose, and a one end reinforced half floating hoseaccording to the different locations of use.

Zebung Technology provides two products, single-frame floating hose and double-frame floating hose, for global customers to use.

Double-frame floating hose refers to a “tube in a tube”. The main skeleton layer is surrounded by the secondary skeleton layer, and the double-frame hose is equipped with a leakage alarm system. When the fluid leaks from the main skeleton layer to the secondary skeleton layer or the main skeleton layer suddenly fails, the detector will respond to the leak, and the operator should replace or remove the damaged hose, which improves work safety to avoid economic losses and environmental pollution. And more importantly, even after the hose has been working for many years, it can ensure that the secondary skeleton layer is still effective.

2、Underwater hose system

Underwater hoses are difficult to replace and have high construction costs, so underwater hoses are required to have high strength and long life, so double-frame underwater hoses are often used.

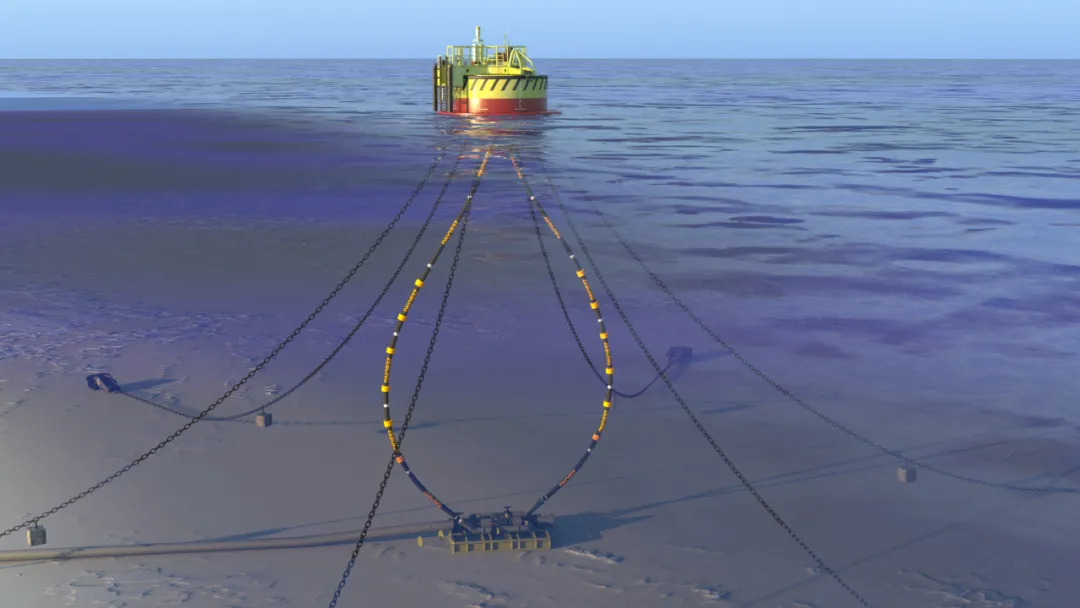

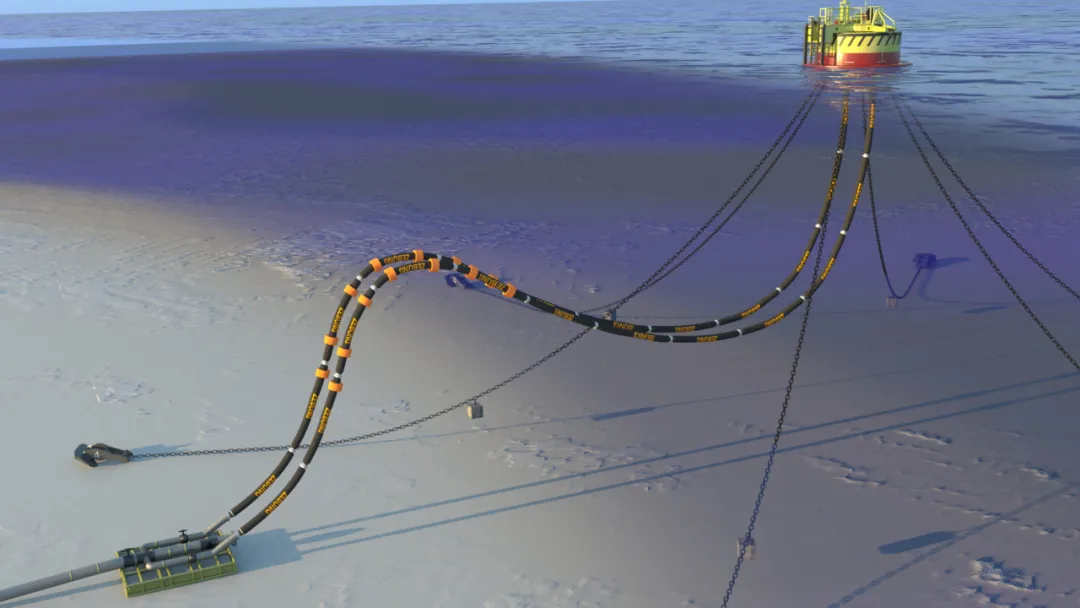

There are three main types of underwater oil hoses: free “S-type”, small-angle “S” type, and Chinese lantern type.

(Chinese lantern type)

Advantages of the Chinese lantern type:

1. The SPM is directly above the PLEM, which greatly eliminates the danger of the tanker bottom colliding with the PLEM and the underwater hose. And the PLEM can also be used as a reference for buoy positioning.

2. The length of the hose used in the Chinese lantern system is much shorter. Therefore, it is less than the hose used in the flat “S” type. In addition to saving money, its advantages are more evident when the hose is replaced.

3. The hose groups are separated from each other, and there is no contact between the tube groups and between the tube groups and the float. The float will not loosen, and there is no danger of divers being clamped when checking the tube groups.

(Small-angle S-type)

(Free S-type)

3、Case

At present, Zebung Technology’s marine oil hoses have been exported to many overseas countries. Busy Southeast Asian ports, crude oil terminals in the Middle East, vast African coastlines, modern North American ports… can all see Zebung marine oil hoses. Zebung Technology not only pursues excellence in products, but also has a global layout in services. The company has established a complete overseas sales and service system, which can provide global customers with rapid response, on-site support and other services, ensuring that marine oil hoses can receive timely and effective technical support and after-sales service in various countries and regions. Zebung Technology looks forward to working with our customers to use the power of technology to jointly draw a grand blueprint for marine energy transportation.

Post time: Jul-11-2024