The inner lining of Zebung chemical hose is made of ultra-high molecular weight polyethylene (UHMWPE), which is mainly due to its excellent physical and chemical properties.

The following is a detailed analysis of the application of ultra-high molecular weight polyethylene in chemical hoses:

1、Characteristics of ultra-high molecular weight polyethylene

1) High wear resistance: The wear resistance of UHMWPE far exceeds that of ordinary materials. This characteristic enables the hose to resist the erosion and wear of the medium during the chemical transportation process and prolong its service life.

2) Corrosion resistance: UHMWPE can resist the erosion of a variety of chemicals, including strong acids, strong alkalis and organic solvents, which provides safety protection for hoses working in complex chemical environments.

3) Chemical stability: Its saturated molecular structure gives it extremely high chemical stability and can maintain stable performance in various corrosive media.

2、 Application areas

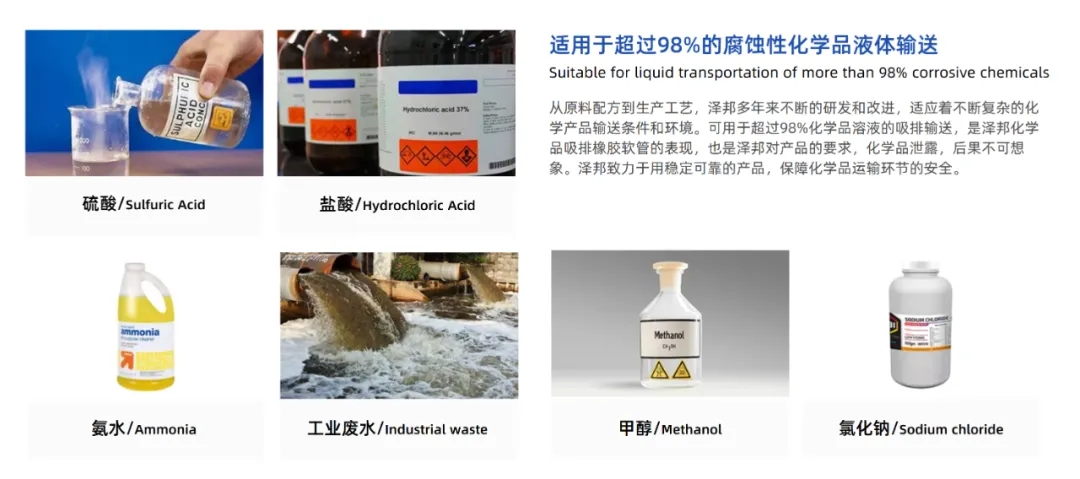

1)Chemical production: On the chemical production line, Zebung’s UHMWPE-lined chemical hose can be used to transport various corrosive liquids and gases, such as sulfuric acid, hydrochloric acid, hydrofluoric acid, etc., effectively protecting production equipment and the environment.

2)Pharmaceutical industry: UHMWPE lined hoses are widely used in the transportation of raw materials and preparations to ensure that the quality of drugs is not affected by pipeline materials.

3) Food and beverages: Due to its non-toxic, odorless and non-bacterial properties, UHMWPE lined hoses are also suitable for the food and beverage industry to ensure the hygiene and safety of products.

4) Textile and papermaking: In the textile and papermaking industry, UHMWPE lined hoses are also favored for their corrosion resistance and wear resistance. 5) New energy industry: Various electrolytes, such as lithium salt solutions, organic solvents, etc., are required in the manufacturing process of new energy batteries. Zebung chemical hoses are used to transport these high-purity electrolytes to ensure that they are not contaminated.

3、 Technical advantages

1) Reduce maintenance costs: High wear resistance and corrosion resistance reduce the replacement frequency and maintenance costs of hoses

2)Improve transportation efficiency: The inner wall of UHMWPE is smooth, which reduces the retention and scaling of the medium in the pipeline and improves the transportation efficiency.

3) Adapt to complex environments: The hose design is easy to install and layout and can adapt to various complex environments and working conditions.

4. Future development trends

1)Material modification: Zebung Technology further improves the comprehensive performance of UHMWPE, such as wear resistance, temperature resistance, and aging resistance, by adding special additives or performing blending modification.

2)Environmental protection and sustainability: Develop recyclable and degradable UHMWPE materials to reduce environmental pollution and promote the development of green chemical industry.

3)Customized services: Provide personalized customized services such as special sizes, colors, connection methods, etc. according to the specific needs of different customers to meet the diversified needs of the market. In summary, the application of ultra-high molecular weight polyethylene (UHMWPE) in chemical hoses has significant advantages and broad prospects. With the continuous advancement of Zebung Technology’s technology and the continuous growth of market demand, lined UHMWPE hoses will surely play an important role in more fields.

Post time: Oct-23-2024