Manufacture r for Mud And Cement Hose - Handling Material Hose – Zebung

Manufacture r for Mud And Cement Hose - Handling Material Hose – Zebung Detail:

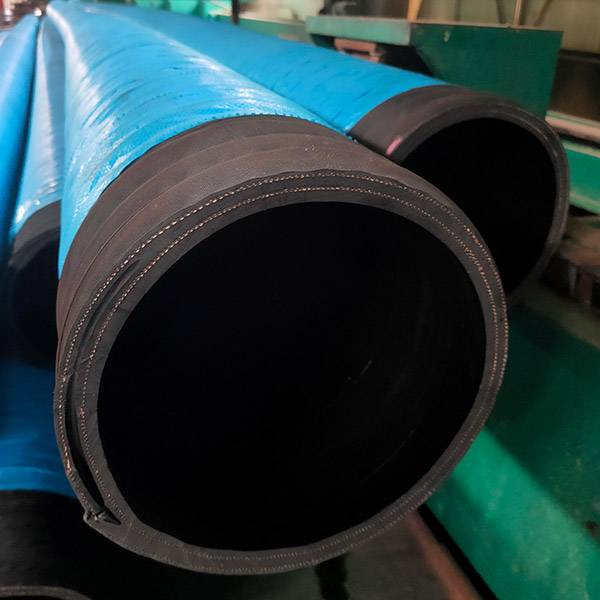

High wear resistant handling material hose

High wear resistant handling material hose

Tube:Black,smooth, NR+BR synthetic rubber.

Reinforcement: High tensile textile cord or high tensile textile cord with helix steel wire.

Cover:Black,smooth(wrapped) or corrugated, abrasion resistant NR synthetic rubber.

Temperature:—20℃(-4℉) ~80℃(+176℉)

Application

Abrasion resistant tube and cover fabricated with highest quality material. Used in the transfer of dry materials & slurry and ideal for dry cement, pebble lime and other abrasive media.

Characteristics

The thickness of the inner rubber tube can be customized according to the actual needs of customers. Single steel wire and double steel wire are provided to meet the needs of different customers. As the operating environment is easy to generate static electricity, we use the method of adding conductive copper wire to eliminate static electricity to prevent fire.

Weather resistant cover/Excellent abrasion resistance/Abrasion loss value:Acc DIN 53516 <=60mm3

|

I.D. |

O.D. |

W.P. |

B.P. |

Tube thickness |

Weight |

Length |

||||

|

mm |

inch |

mm |

psi |

bar |

bar |

mm |

kg/m |

ft |

m |

|

|

51 |

2″ |

66 |

150 |

10 |

450 |

30 |

4 |

1.73 |

200/130 |

61/40 |

|

64 |

2-1/2″ |

80 |

150 |

10 |

450 |

30 |

4 |

2.4 |

200/130 |

61/40 |

|

76 |

3″ |

94 |

150 |

10 |

450 |

30 |

5 |

3.18 |

200/130 |

61/40 |

|

102 |

4″ |

121 |

150 |

10 |

450 |

30 |

5 |

4.26 |

200/130 |

61/40 |

|

127 |

5″ |

146 |

150 |

10 |

450 |

30 |

5 |

5.55 |

200/130 |

61/40 |

|

152 |

6″ |

173 |

150 |

10 |

450 |

30 |

6 |

7.27 |

200/130 |

61/40 |

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for Manufacture r for Mud And Cement Hose - Handling Material Hose – Zebung , The product will supply to all over the world, such as: Brasilia, Munich, Tunisia, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

Leave your details and we'll contact you at the first time.