Liquid Petroleum Gas Rubber Hose (LPG hose)

Liquid Petroleum Gas Rubber Hose (LPG hose)

The suction and discharge hose is specially designed for LPG/LNG offshore transfer, LPG hoses have been widely used for LPG transfer in dock-side applications. LPG hose construction for a given application depends upon the product being transferred and the operational parameters. In particular, refrigerated LPG has a different set of hose system transfer requirements to that of LPG at ambient temperatures.

Construction:

Tube: NBR

Reinforcement layer: High tensile textile cord with helix steel wire

Cover: NBR +CR

Safety factor: 5:1

Temperature Range:

-40℃-- +80℃

Technical parameters:

|

I.D. |

O.D. |

W.P. |

B.P. |

B.R. |

Weight |

Length |

||||

|

mm |

inch |

mm |

psi |

bar |

psi |

bar |

mm |

kg/m |

ft |

m |

|

25 |

1" |

38 |

150 |

10 |

450 |

30 |

254 |

0.93 |

196 |

60 |

|

32 |

1-1/4" |

45 |

150 |

10 |

450 |

30 |

330 |

1.25 |

196 |

60 |

|

38 |

1-1/2" |

51 |

150 |

10 |

450 |

30 |

381 |

1.47 |

196 |

60 |

|

51 |

2" |

64 |

150 |

10 |

450 |

30 |

508 |

1.92 |

196 |

60 |

|

64 |

2-1/2" |

78 |

150 |

10 |

450 |

30 |

635 |

2.51 |

196 |

60 |

|

76 |

3" |

93 |

150 |

10 |

450 |

30 |

762 |

2.9 |

196 |

60 |

|

102 |

4" |

118 |

150 |

10 |

450 |

30 |

1016 |

3.92 |

196 |

60 |

|

125 |

5" |

145 |

150 |

10 |

450 |

30 |

1270 |

6.99 |

196 |

60 |

|

152 |

6" |

174 |

150 |

10 |

450 |

30 |

1524 |

8.99 |

196 |

60 |

|

Note: other size and floating LPG hose are available |

||||||||||

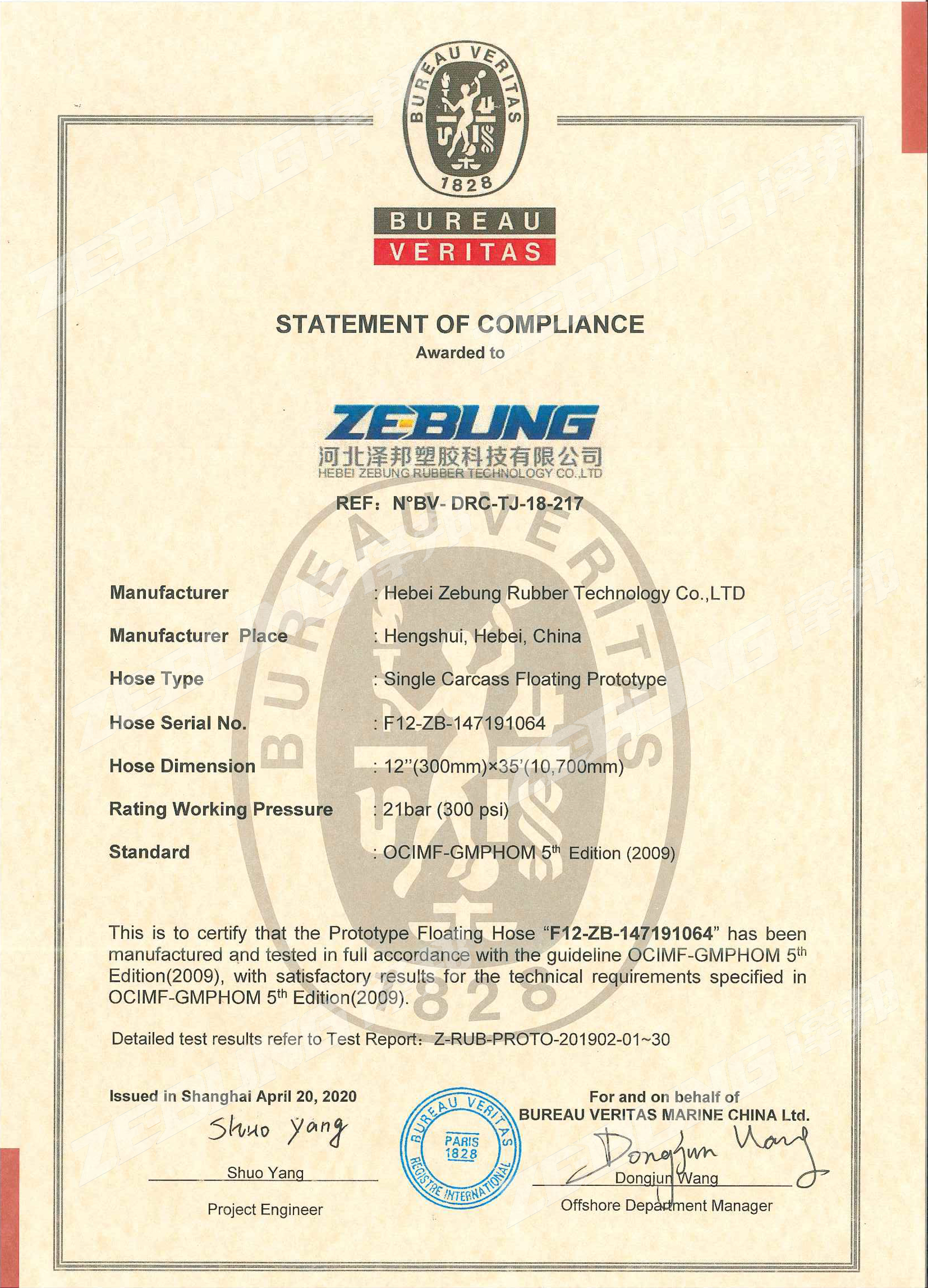

Single Carcass Floating(300mm) Prototype BV certificate

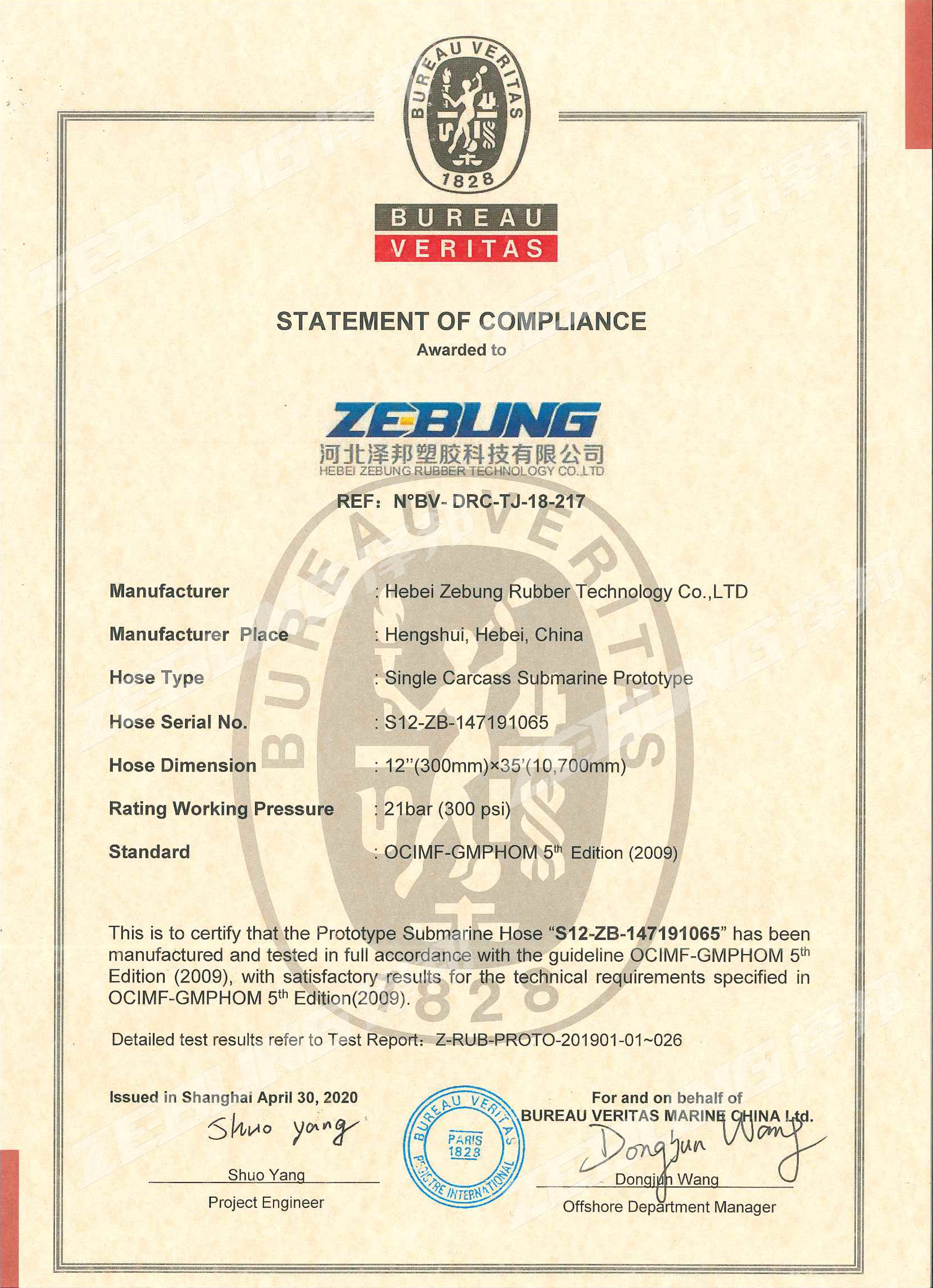

Single Carcass Submarine(300mm) Prototype BV certificate

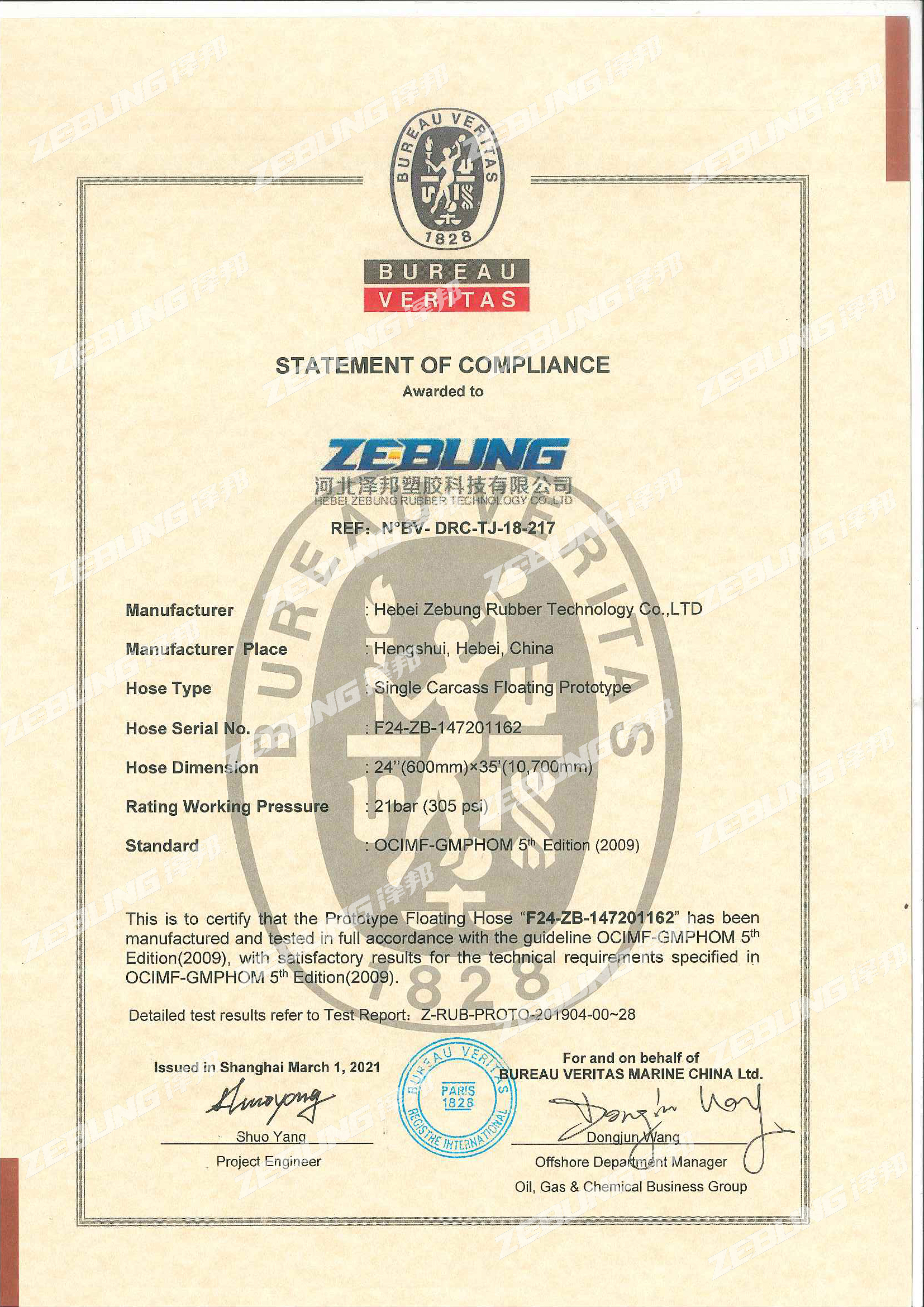

Single Carcass Floating(600mm) Prototype BV certificate

Single Carcass Submarine(600mm) Prototype BV certificate

11.jpg)

Floating Double Carcass Prototype BV certificate

1.jpg)

Submarine Double Carcass Prototype BV certificate

1.jpg)

Own film production base

The quality of film directly determines the quality of hose. Therefore, zebung has invested a lot of money to build a film production base. All hose products of zebung adopt self-produced film.

Multiple production lines to ensure production progress

Our factory has many modern production lines and a large number of experienced technical engineers. It not only has high quality production quality, but also can ensure the customer's requirements for the supply time of products.

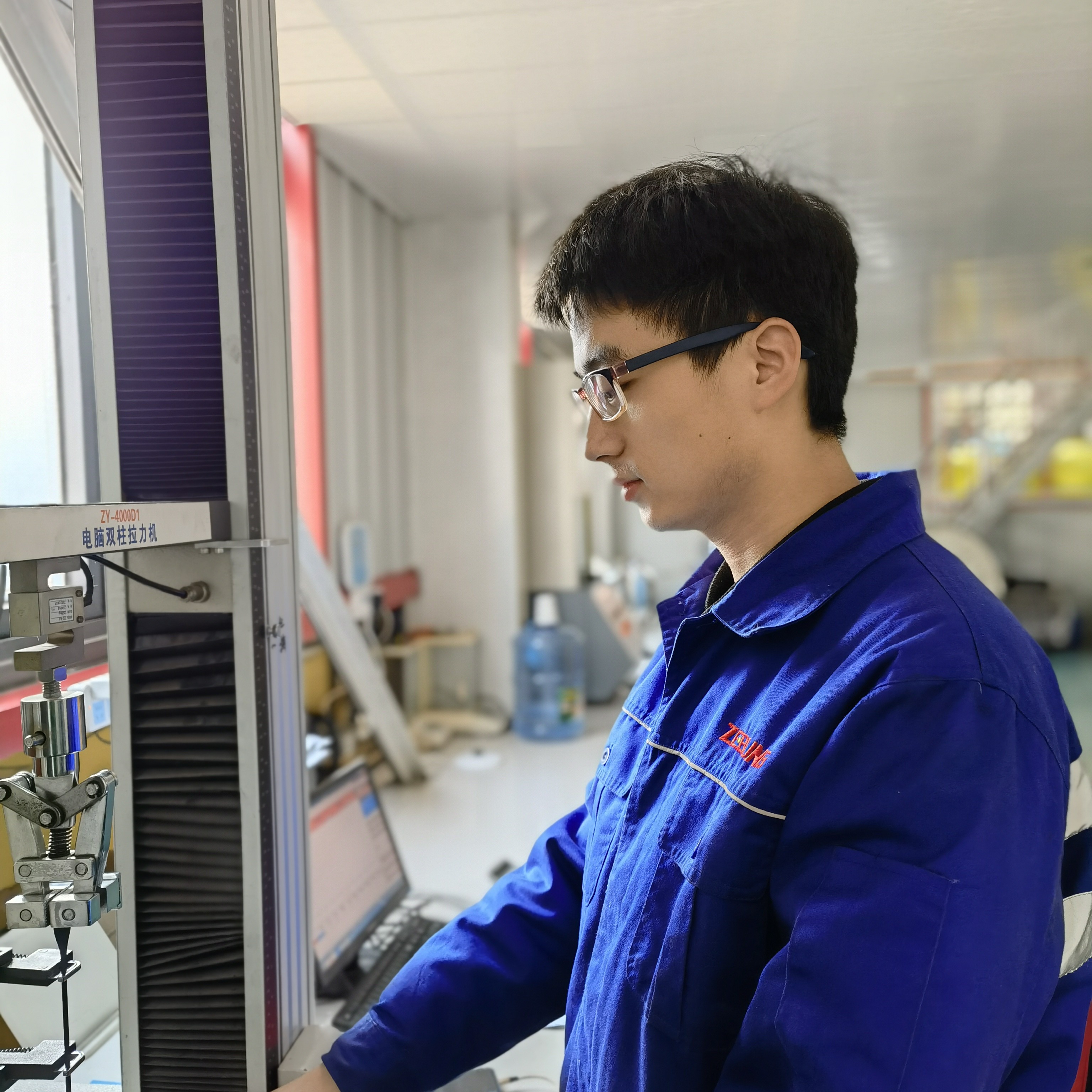

Each pipeline product is subject to strict inspection before leaving the factory

We have established a high-tech product and raw material testing laboratory. We have been committed to the digitization of product quality. Each product needs to go through a strict inspection process before it can leave the factory after all product data meet the requirements.

Covering the global logistics network and strict finished product packaging and delivery process

Relying on the distance advantages of Tianjin port and Qingdao port, Beijing Capital International Airport and Daxing International Airport, we have established a fast logistics network covering the world, basically covering 98% of countries and regions around the world. After the products are qualified in the off-line inspection, they will be delivered at the first time. At the same time, when our products are delivered, we have a strict packing process to ensure that the products will not cause losses due to logistics during transportation.

Leave your details and we'll contact you at the first time.