11.8m Dock Oil/Gas/LPG Hose

Dock /Cargo oil hose

Dock Oil Transfer Hose Construction:

Tube: Black,smooth,Nitrile synthetic rubber,suitable for up to 50% aromatic content.

Reinforcement: Multiply heavy duty synthetic tire cord supported with helix wire, anti-static wires.

Cover: Black, wrapped finish, synthetic rubber for high abrasion , ozone & weather resistance.

Ideal Temperature: -40℃ to +100℃( 180℉)

Safety factor:5:1

Dock Oil Transfer Hose Characteristic:

C/W built-in flanges with one side fixed and one side swivel ,ANSI150 standard.

Application

Dock oil hose is designed for maximum service life in petroleum product and refined fuel transfer at up to 300 PSI service pressure. This dock hose design is beneficial where a higher working pressure or a heavier wall for abrasion is desired. Dock hoses are heavy duty suction and discharge hoses designed to transfer between bargers, storage tanks and marine vessels. These hoses incorporate a specially formulated tube to resist media to 50-100% aromatic content., while the cover is ozone and weather resistant for a long service life. Rugged cover is resistant to oil, cuts, scuffs, and ozone attack.

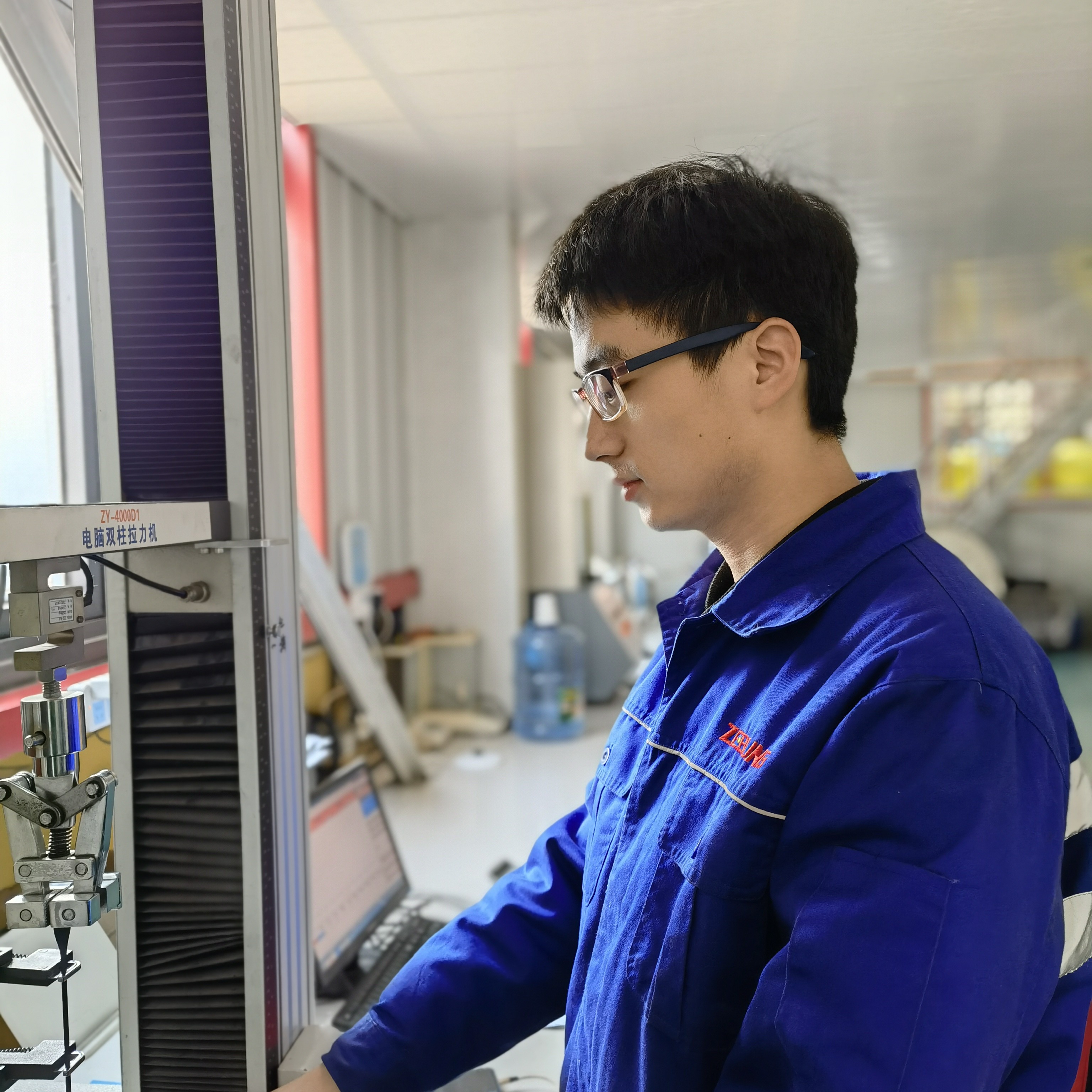

Test Equipment: Mooney Viscosity and Relaxation Tester; Uv lamp aging test box;

heat aging test chamber ; Ozone Aging Chamber; Abrasion Test.

Dynamic Tension Test Machine,Bending Test Machine.

Laboratory of Homologations and Tests: the prototypes developed by the team of engineering and design are subjected to multiple tests and stress tests in our own laboratory.

In this laboratory we also periodically test all products that are made here

Manufacture and own technology: once each new product has passed all the test and homologations, this happens to our manufacturing plant equipped with technology of last generation.

| size | I.D. | W.P. | Length |

| 6 inch | 150mm | 10~20 | 11.8m |

| 8 inch | 200mm | 10~20 | 11.8m |

| 10 inch | 250mm | 10~20 | 11.8m |

| 12 inch | 300mm | 10~20 | 11.8m |

| 16 inch | 400mm | 10~20 | 11.8m |

| 20 inch | 500mm | 10~20 | 11.8m |

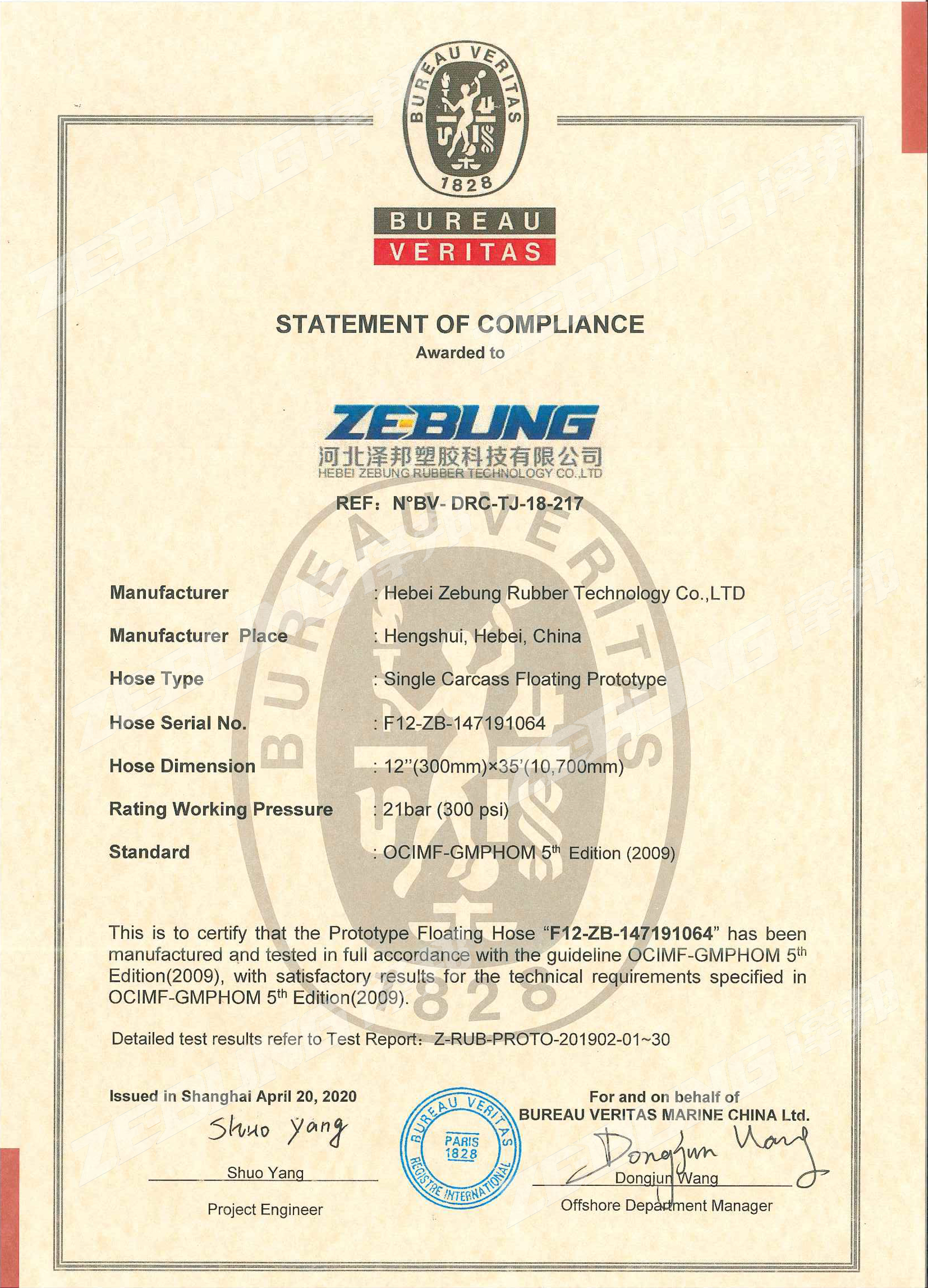

Single Carcass Floating(300mm) Prototype BV certificate

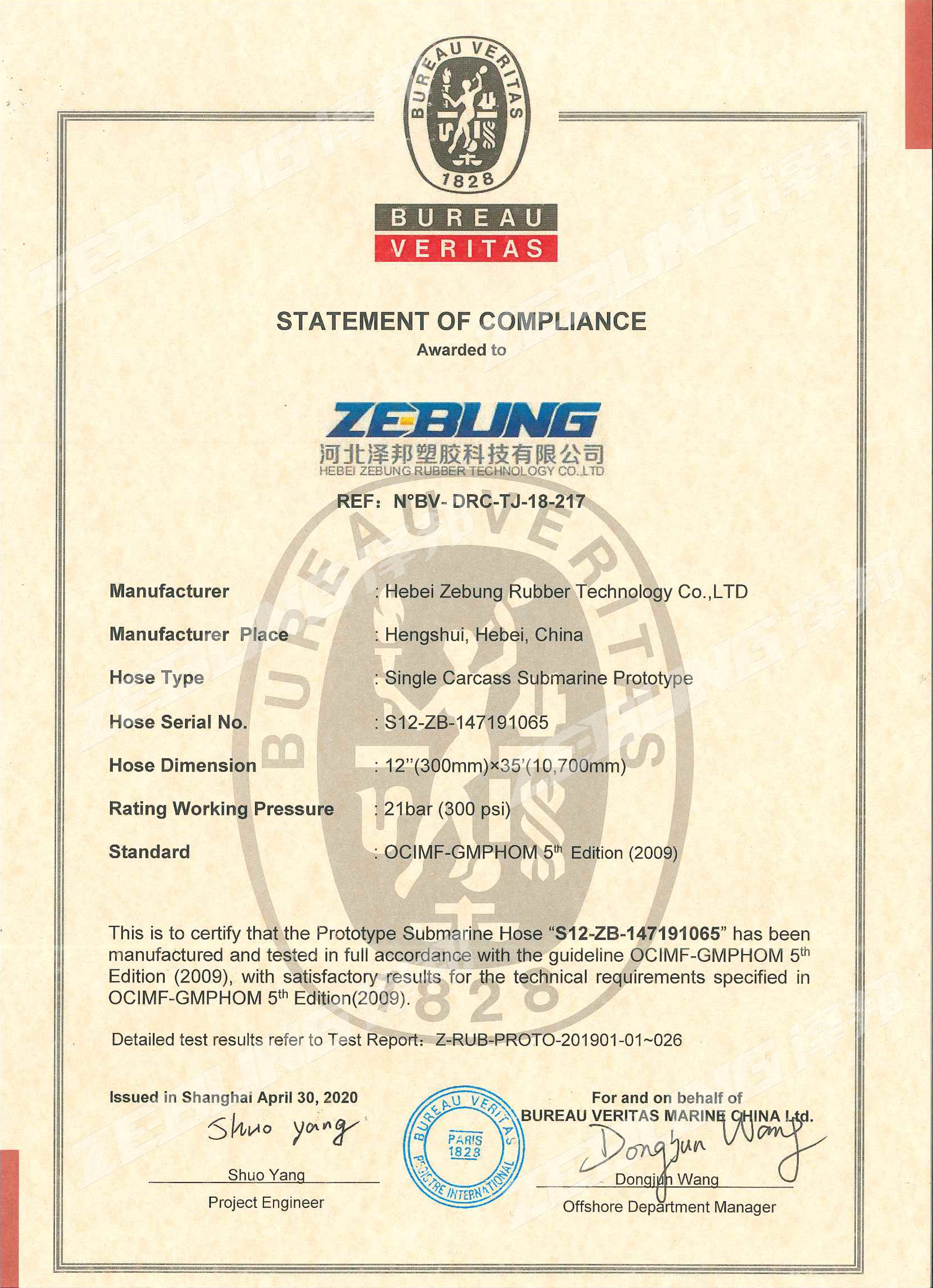

Single Carcass Submarine(300mm) Prototype BV certificate

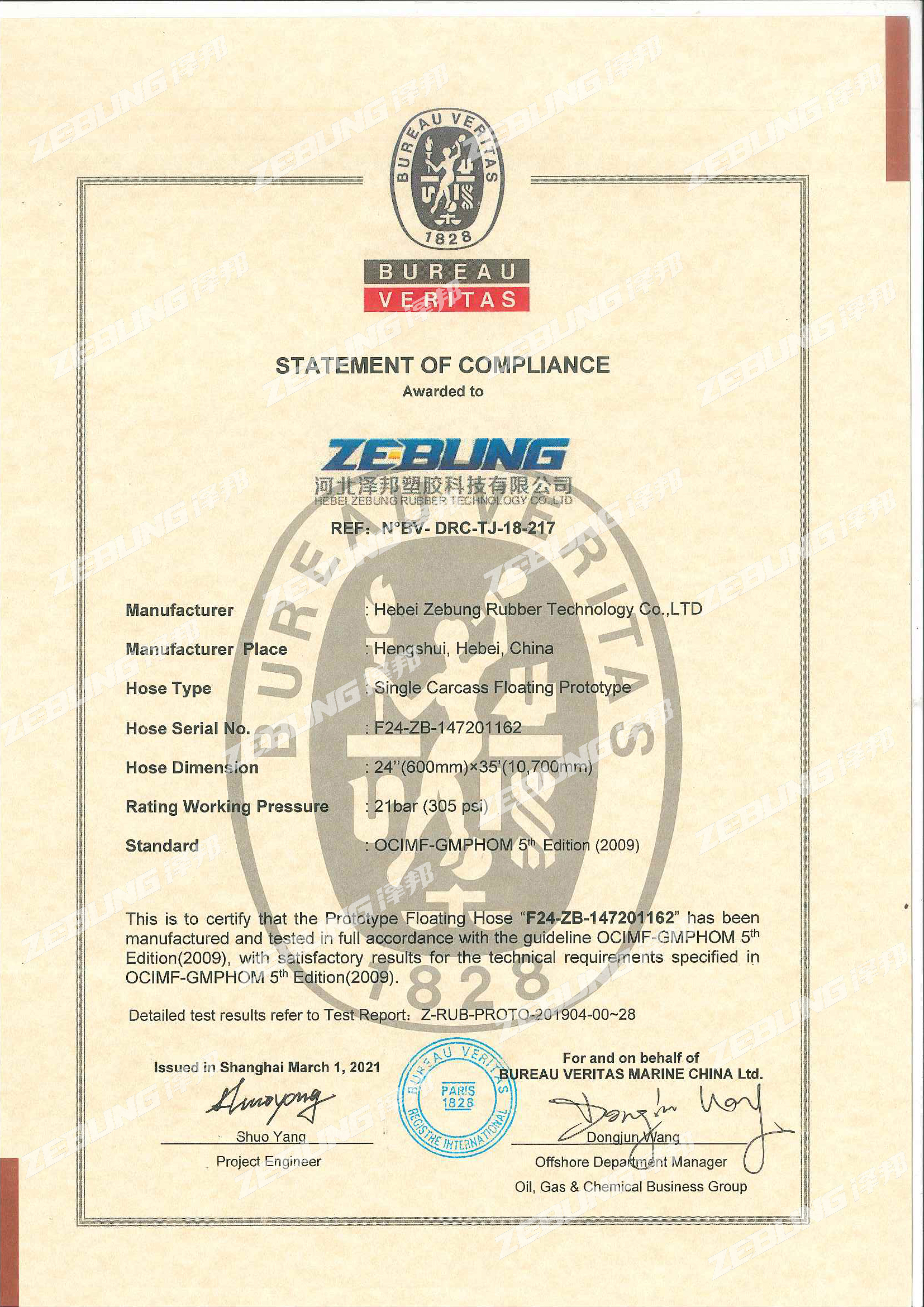

Single Carcass Floating(600mm) Prototype BV certificate

Single Carcass Submarine(600mm) Prototype BV certificate

11.jpg)

Floating Double Carcass Prototype BV certificate

1.jpg)

Submarine Double Carcass Prototype BV certificate

1.jpg)

Own film production base

The quality of film directly determines the quality of hose. Therefore, zebung has invested a lot of money to build a film production base. All hose products of zebung adopt self-produced film.

Multiple production lines to ensure production progress

Our factory has many modern production lines and a large number of experienced technical engineers. It not only has high quality production quality, but also can ensure the customer's requirements for the supply time of products.

Each pipeline product is subject to strict inspection before leaving the factory

We have established a high-tech product and raw material testing laboratory. We have been committed to the digitization of product quality. Each product needs to go through a strict inspection process before it can leave the factory after all product data meet the requirements.

Covering the global logistics network and strict finished product packaging and delivery process

Relying on the distance advantages of Tianjin port and Qingdao port, Beijing Capital International Airport and Daxing International Airport, we have established a fast logistics network covering the world, basically covering 98% of countries and regions around the world. After the products are qualified in the off-line inspection, they will be delivered at the first time. At the same time, when our products are delivered, we have a strict packing process to ensure that the products will not cause losses due to logistics during transportation.

Leave your details and we'll contact you at the first time.